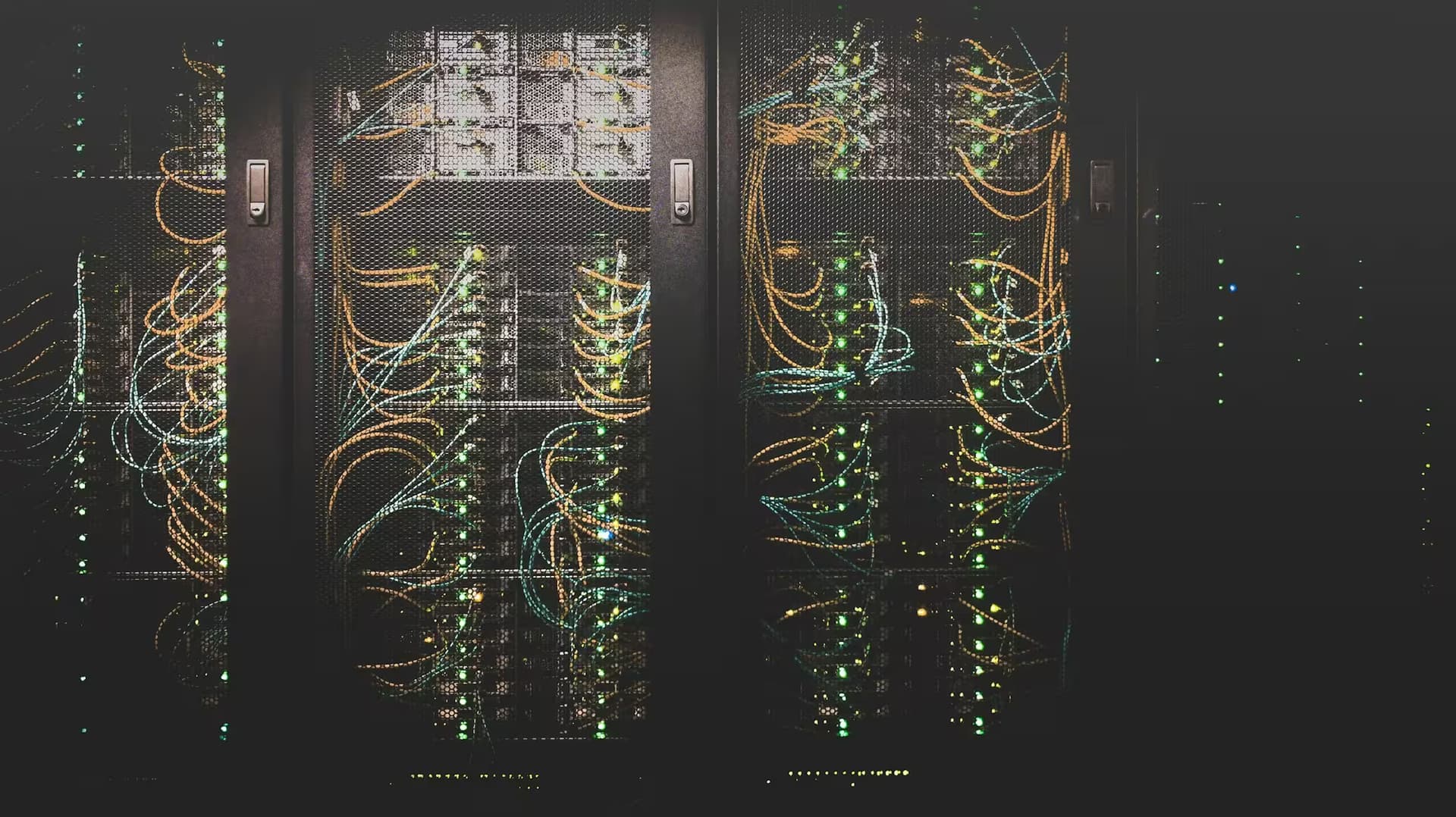

Digitalization in manufacturing?

Without operational risk.

Digitalization in manufacturing without operational risk: MES, ERP, SCADA, IoT – many systems, but no single source of truth. We integrate your production data so that KPIs are accurate and decisions become faster.

30 min. initial consultation – 100% free & no obligation

Typical Challenges

Does this sound familiar?

Data Silos

MES, ERP, SCADA deliver different numbers

Media Breaks

Excel, emails, manual handoffs in daily operations

Unclear KPIs

OEE and other metrics not traceable

Legacy Systems

Old plant controls difficult to integrate

Security Concerns

OT/IT separation unclear, access risks

No Real-Time

Decisions based on outdated data

Concrete Solutions

How We Digitalize Your Manufacturing

| Your Problem | Our Approach | Your Result |

|---|---|---|

| Systems deliver different data | Integration with data contracts | One source of truth for all departments |

| KPIs not traceable | Semantic KPI layer (OEE etc.) | Consistent, audit-proof metrics |

| Manual processes and Excel | Workflow automation | Fewer media breaks, faster processes |

| Legacy systems hard to connect | API facades + adapters | Old systems securely integrated |

| Security risks with OT/IT | Zone models + least privilege | Secure access, clear responsibilities |

Typical Projects

Use Cases We Implement

Transparency & KPI Layer

A semantic KPI layer makes metrics consistent – regardless of source or location.

Real-Time Events

Status events from equipment trigger workflows: maintenance, replenishment, quality checks.

Partner Integration

Connect suppliers and customers via stable interfaces – with monitoring and SLAs.

Gradual Modernization

Legacy functions are decoupled and replaced without production stops.

Planning Manufacturing Digitalization?

In 30 minutes, we'll discuss your current situation and show you how we securely integrate your systems.

- Free initial consultation

- OT/IT expertise

Is automation in manufacturing worth it?

Compare manual process costs with an automation investment – including break-even point.

Frequently Asked Questions

FAQ Manufacturing & Industry

How do we integrate OT and IT securely?

Through zone models, least privilege, audit logs, and clear deployment processes. We respect maintenance windows and build failover/backups in from the start.

How do we ensure data quality?

Through data contracts, quality gates, and a clear owner per data product. This makes KPIs like OEE traceable and audit-proof.

How quickly are initial results visible?

Often quickly: transparency dashboards, monitoring, and initial automations take effect within a few weeks, while the platform grows incrementally.

What does an industry project cost?

A workshop + integration map starts at approx. €5,000. Implementation depends on scope – we work with clear milestones.

Questions about your industry project? We're happy to advise you.

Book Consultation